In consumer marketing, consumers make buying decisions based on certain mental stages such as need recognition, information search, evaluation, purchase decision, and post-purchase behavior. But, in industrial markets the buying decision making process includes observable sequential stages involving many people in the buying organisation. The understanding of these steps/phases of buying-decision making is helpful to an industrial marketer to develop an appropriate selling strategy.

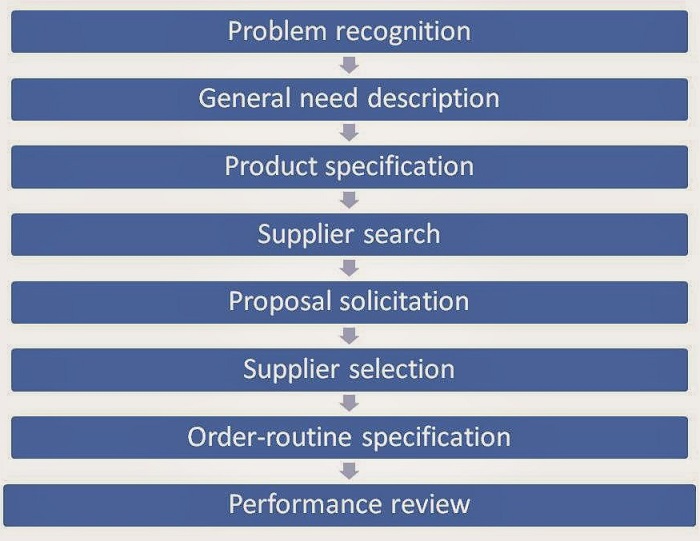

The purchasing activities of industrial buyers consist of various steps/phases in buying decision making process. The importance of each step depends upon the type of buying situation. The industrial marketers should understand both (step in decision-making process and the type of buying situations) to market the product or service. In 1967, Robinson, Faris, and Wind developed a process “buy-phases” having eight steps in buying-decision process in industrial market. These phases or steps in industrial buying process are elaborated as follows:

1. Recognition of Need of Industrial Buyer

A smart marketer recognizes the need/problem of industrial buyer originated within the firm. If the material supplied by the existing supplier is not satisfactory in terms of quality, or the material is not available as per requirement, or the machine supplied by him breaks down too often, the buying organisation recognizes the problem. If an industrial marketer identifies a problem in the buying organisation and suggests how the problem could be solved, there will be a better possibility of it being selected as a supplier.

2. Determination of the Characteristics and Quantity of Needed Product

If the problem is recognized within or outside the buying organisation, then the buying firm will try to answer questions such as: What type of products or services to be considered? What quantity of the product needed? and so on. For technical products, the technical departments (R&D, industrial engineering, production, or quality control) will suggest general solutions of the needed product. For non-technical goods or services, either the user department or purchase department may suggest products or services, based on experience and also the quantity required to solve the problem. Nevertheless, if the required information is not available internally within the buying organization, the same can be obtained from the outside sources.

3. Development of Specification of Needed Product

Stage 2 and 3 are closely related. After the general solution to the problem is determined in the second phase, the buying organisation, in the third stage, develops a precise statement of the specifications or characteristics of the product or service needed. During this stage the purchase department takes the help of their technical personnel, or if required, outside sources such as suppliers or consultants. Industrial marketers have a great opportunity to get involved at this stage by helping the buyer organisation to develop product specifications and characteristics. It would give a definite advantage by ensuring that the needed product includes his or her company’s product characteristics and specifications.

4. Search the Qualified Potential Suppliers

In this stage, the buying organisation searches for acceptable suppliers or vendors. Firstly, they have to obtain information about all available suppliers and secondly, they have to decide the qualifying suppliers. The search for potential suppliers is based on the various sources of information like trade journals, sales calls, work-of-mouth, catalogues, trade-shows, industrial directories. The qualifications of acceptable supplies may depend on the type of buying organization such as government undertaking, private sector commercial organisation, or institutions, and the buying situation, and the decision-making members. Furthermore, the factors like quality of product or service, reliability in delivery, and service are considered in qualifications of suppliers.

5. Obtaining and Analyzing Supplier Proposals

If the qualified suppliers are decided then the buying organisation obtains the proposals by sending enquiries to the qualified suppliers. A supplier’s proposal can be in the form of a formal offer, quotation, or a formal bid, submitted by the supplier to the buying organisation. It must include the product specification, price, delivery period, payment terms, taxes and duties applicable, transportation cost (or freight), cost of transit insurance, and any other relevant cost or free service provided. For purchases of routine products or services, the stages 4 and 5 may occur simultaneously, as the buyer may contact the qualified suppliers to get the latest information on prices and delivery periods. For technically complex products and services, a lot of time is spent in analyzing proposals in terms of comparisons on products, services, deliveries, and the landed costs: includes the price after discount plus excise duty, sales tax, freight, and insurance.

6. Evaluation of Proposals and Selection of Suppliers

The industrial buyers evaluate the proposals of competing suppliers and selects one or more suppliers. Further negotiations may continue with selected suppliers on prices, payment terms, deliveries, and so on. The decision makers in the buying organization may evaluate each supplier on a set of agreed-upon attributes or factors. Each supplier is evaluated on each attribute by giving a weightage to each attribute proportionately or on rating scale basis. The supplier(s) who get the highest total score receives the business or the order from the buying organisation. If a buying firm faces a make-or-buy decision, the supplier’s proposals are compared with the cost of producing the needed item within the buying organization. If it is decided to make the item within the buying organization, the buying process is stopped at this stage.

7. Routine Order Selection

In this stage the procedure of exchange of goods and services between a buyer and a seller is worked out. The activities include placement of orders (i.e. purchase orders) with the selected suppliers, the quantity to be purchased from each supplier, frequency of order placement by buyers and delivery schedules to be adhered to by the supplier, schedule, and the payment terms to be adhered to by the buyer. The user department would not be satisfied until the supplier delivers the required item as per delivery schedule, and with acceptable quality.

8. Performance Feedback and Post-Purchase Evaluation

In this final phase a formal or informal review regarding the performance of each supplier (or vendor) takes place. The user department gives a feedback on whether the purchased item solved the problem or not. If not, the members of the decision-making unit review their earlier decision and decide to give a chance to the previously rejected supplier. The industrial vendor should recognize that marketing effort is no over after the order is received. He or she must check the feedback and evaluation process in the customer (buyer) organisation. In particular, the industrial marketer must monitor the user satisfaction levels or complaints so that immediate corrective action can be taken before a major damage. In fact, a quick response to customers’ complaints can result in good buyer-seller relationship. The type of products, the phase of the buying-decision making process of customer firms, and the purchasing situations also influence the marketing strategy of industrial seller.

Download PowePoint Presentation: Industrial-buying-process (pptx)