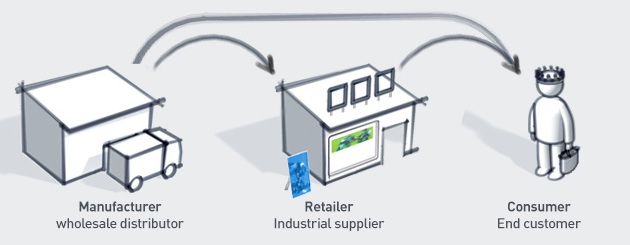

When a company or a manufacturer produces goods or services, it has the immediate responsibility to distribute and sell them to the industrial and institutional customers. The industrial customers generally constitute of wholesalers, retailers, manufacturers, educational institutions, governments, hospitals, public utilities, and other formal organizations. There are various intermediaries who are involved in a distribution and selling process helping the manufacturers to make their goods reach the end users. Thus, a network or channel that helps to flow the goods from the producer to the consumer through a set of interdependent organizations (intermediaries) is called distribution channel or trade channel or marketing channel. Channels are the tools used by management to move the goods from the place of production to the place of consumption. In the progression, the title of goods gets transferred from sellers to buyers.

Industrial distribution is unique as there are several different methods of channeling the products and services to industrial consumers. The type of product, the selling price of the product and technical knowledge required to sell the product all play a considerable role in selecting the proper sales or distribution channel. Unlike consumer organizations, the decisions taken by the industrial organizations on distribution channels is of great significance as the decisions involved are of long-term nature that cannot be changed frequently. The industrial organizations carry on certain important functions till the products reach the consumers — like utilizing the services of transportation companies for distribution, the services of warehouses for safe storage of goods, inventory control, order processing and selection of marketing channels. This necessitate taking important decisions like devising effective communication tools, planning promotional activities, managing finances etc that help in serving the consumers better.

The Nature of Industrial Distribution Channel

The nature of industrial distribution channel is quite different from the consumer goods distribution channel. The intermediaries stock the products they are distributing thereby assuming part of the burden of marketing the product and maintaining close contact with customers. There are various factors that affect the distribution of industrial goods.

- Geographical Distribution: The industrial distributors are concentrated highly in the industrial markets they serve and certain other places that have large number of industries like large towns and cities.

- Size: Unlike consumer markets, the industrial markets tend to have fewer channels of distribution. Even the industrial channel is shorter in size as organizational buyers expect immediate product availability, technical expertise and prompt after-sales service. This indirectly demands investment in training and physical facilities for the industrial organizations.

- Intermediary characters: The intermediaries involved in industrial marketing are technically qualified who maintain very close relationship with industrial organizations. Industrial manufacturers tend to depend more heavily on each member of the channel and may do more to support that channel member. Industrial distributors, brokers and agents are some types of intermediaries used by industrial marketers to reach customers.

- Mixed channels: A combination of direct and indirect channels is used by some industrial marketers to cater to different market segments or when they have some resource constraints. To cater to large-volume customers, industrial firms generally use their own sales force, and to cover small scale organizations, they use independent distributors. In case of large geographical territories, due to resource constraints they use their agents called as ‘manufacturers representatives’.

The Structure of Industrial Distribution Channel

There are different ways in which an industrial distribution channel can be structured. Some of the industrial distribution channel structures are direct while some are indirect.

Direct Channel Structures

In direct channel structures, the entire task necessary to create sales and to deliver the products to industrial customers is performed by the manufacturers themselves. The various tasks involved in this process are contacting the potential customers, communicating and negotiating with them, financing and selling, storing the products, transportation and providing related services. This approach is viable to the company only if:

- The buying process is lengthy,

- The selling includes extensive technical and commercial negotiations at various levels, including top management,

- The industrial buyer insists on buying directly from the manufacturer, and

- The value of each transaction is large.

Some of the examples of direct channel are direct sales (through the company sales force) and direct marketing (through direct mail, telemarketing, Internet marketing)

Indirect Channel Structures

In indirect channel structures, the various tasks discussed above is shared both by the manufacturer and the intermediaries. An indirect distribution approach is appropriate when:

- The industrial buyers are widely dispersed,

- The value of transaction or sales are low,

- The industrial buyers purchase many product items in one transaction, and

- The manufacturer has limited resources.

Some of the examples of indirect channel are manufacturer’s representatives (or agents), brokers, commission merchants, commission merchants, industrial dealers or distributors, value-added resellers, jobbers, drop shippers. Indirect distribution is used in industrial chemicals, construction materials, electrical wiring materials and supplies, general industrial machinery, iron and steel products, etc..

Types of Industrial Middlemen

The industrial middlemen are the intermediaries used by the manufacturers to deliver their products to the end users. They are categorized based on the number and the extent to which they specialize in the performance of certain functions. Different types of industrial middlemen are manufacturers representatives (also called agents), brokers, commission merchants, industrial dealers or distributors, value-added resellers (VARs), jobbers and drop shippers.

- Manufacturers Representatives: The manufacturers representatives (sales agents or manufacturers agents) are very commonly seen middlemen who secure orders from existing and potential customers. They provide relevant information on market conditions to the manufacturers as well as customers. They are paid a certain amount of pre-specified commission on sales and other tasks performed to make the sales. Generally small and medium-sized industrial firms use the services of agents in territories with low market potential. Agents are cost-effective for them because commission is paid as per the orders generated. The agents particularly have good knowledge about the product, their target market apart from excellent contacts with the buyers.

- Brokers: Brokers are the middlemen who represent either the buyer or the seller. They help the manufacturer to find potential buyers and vice versa and take the commission when sales process is complete.

- Commission Merchants: They deal with large quantities of items like raw materials. They are paid commission by the manufacturers when they perform certain functions. Their general functions include getting the raw materials inspected, negotiating during sales and finally close the sales. They receive the commission based on the net sales value as is compensated to agents and brokers.

- Industrial Distributors: Industrial distributors are the important and most preferred middlemen that are typically small and independent serving narrow geographic markets. They perform functions like buying, transportation and warehousing, promotion and selling, and offering credit. Because of such varied functions, they are sometimes referred to as full function intermediaries. They are offered trade discounts on the price list of the products as their compensation. Industrial distributors are categorized as general line distributors or mill supplies houses that stock wide variety of products and sell to a diversified group of customers. They are referred to as the supermarkets of industry. The products stocked by them include maintenance repair and operating (MRO) supplies, original equipment manufacturer (OEM) supplies, and equipment used in the operation of a business, such as hand tools, power tools and conveyors etc. The second type of distributors known as specialized distributors specializes in products they handle or customers they serve. Because of increase in specialized markets, their numbers are increasing. Specialized distributors limit their inventories to specific product range like bearings, office equipment and supplies, electrical equipment and supplies, or abrasives etc. The third category called the combination house sell directly to industrial customers as well as some other retailers or dealers.

- Value-added Resellers (VARs): They add some value or feature to an existing product and sell to end-users as a new package. This is found often in the computer industry, where a company purchases computer components and builds a fully operational personal computer. By doing this, the company has added value above the cost of the individual computer components. Customers would purchase a computer from the reseller to either save time or if they do not have the skills to build a unit themselves.

- Jobbers: They get orders from the customers and pass them to the manufacturers. Though they do not handle the goods physically in any form, they take the title to the products they sell. Jobbers specialize in marketing bulky products like coal, iron ore etc, that are transported in huge quantities and do not require assorting or grouping of products.

- Drop Shippers: When an online marketer has certain concerns like where to get the goods from, where to store them until they are sold, and what amount to charge for shipping the goods to the customers, then drop shippers come to the rescue of such marketers who work with merchants to move the products. Drop Shipping is generally used by web site owners, shop owners and mail order firms who do not stock inventory of the products sold for future delivery through mail order, catalog and internet advertising. Middlemen send single unit orders for products to manufacturers, or major stocking distributors, who in turn drop ship the merchandise direct to the customers of the middlemen. Manufacturers providing drop shipping services can gain additional sales, shift advertising costs to middlemen, offer advertising material and reduce inventory requirements. Middlemen who initiate drop ship orders shift the risks of stocking inventory to the supply source, including storage, insurance, overhead, and personnel by spending nothing on inventory.

The Functions and Responsibilities of Distributors

Nothing prevents a producer from meeting his customers directly and effecting sales. If he does not use this privilege, he has to borrow the services of different middlemen who act as a vital link in the distribution network to pass on the production to the actual users. A full function intermediary or the distributor performs all or most of the distribution functions like:

- Purchasing products from the producer to resell back to the industrial buyers

- Promoting the product through ads, negotiating by offering discounts and securing orders from customers

- Extending credit to customers while reselling the products

- Storing the products safely at warehouses and ensuring its availability to the customers

- Inspecting and testing the product, and assigning distinct quality grades. (Various grades of products are sold to different end users at different prices)

- Transporting the product from warehouses to customers place

- Providing information on product features, price etc., to the customers and competition, market demand etc., to the manufacturers.

- Providing pre-sales and after-sales services to the customers through their technical service personnel.

As the intermediaries perform all or most of the above functions, the industrial marketers find it more suitable to use their services rather than doing all the things by themselves. But, they should analyze certain functions that are very important for them but cannot be performed effectively due to reasons like cost effectiveness or service inefficiency. Such tasks should be outsourced to those intermediaries who have the expertise to perform them effectively and efficiently.

Reasons Industrial Customers prefer Distributors

There are many reasons why industrial customers buy from distributors. Some of the common reasons include:

- Delivery: Industrial customers particularly the small scale manufacturers find the distributors to be more reliable who delivers them goods in less time and at a lesser price. This helps them reduce their inventory level as well as the inventory carrying cost.

- Information: Distributors provide relevant information on various products like technical information, price, availability, quality that helps the customer select and buy the best.

- Variety: The distributor stocks variety of products at one place that caters to all the requirements of the industrial buyers.

- Credit: The distributor offers credit facility to his reputed and credible buyers whenever they purchase from him.

Besides above, it is the relationship and best customer service that matters the most to the customers to prefers a particular distributor.

Manufacturer and Distributor – Partners in progress

Though there would be lot of conflicts and disputes existing between the manufacturer and the distributor, both need to maintain good relationship that help them to be partners in progress. The manufacturer should provide the distributor with all the assistance that is economically feasible to enhance the distributor’s performance. The assistance from the manufacturer could be in the form of:

- Providing increased margins or financial help that stimulates the distributor to increase inventory levels

- Improving distributor’s performance through deploying its sales force where supplemental technical support can be provided or joint sales calls can be done

- Imparting technical and general training to the distributor personnel to improve their effectiveness and strengthen the bond.

Simultaneously, the distributors should also execute all their basic functions and meet their responsibilities (that have been discussed earlier) in a systematic way that would help the manufacturer perform better. In addition, they should recognize the significant trends unfolding in the industry by understanding the market dynamics and forecasting its future directions. Eventually, the efforts of both the ‘partners in progress’ should be to grow together that can happen only through mutual coordination and understanding each other in a better way.

Read More:

External Links:

- Channels of Distribution (Business.gov.in)

- Distribution Channels (Inc)