Method study is the systematic recording and critical examination of existing and proposed ways of doing work, as a means of developing and applying easier and more effective methods and reducing costs. So it is the process of analyzing the methods involved in work flow to increase productivity. It deals with doing the work in a better way, with less time and effort. That is why it is also termed as work simplification.

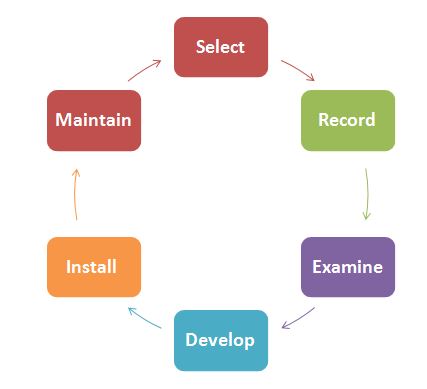

Method study procedure is an organized approach and its investigation rests on the following six basic steps:

- Select the work to be analyzed.

- Record all facts relating to the existing method.

- Examine the recorded facts critically but impartially.

- Develop the most economical method commensurate with plant requirements

- Install the new method as standard practice.

- Maintain the new method.

The above basic method study procedure was first developed and articulated by Russell Currie at Imperial Chemical Industries (ICI).

1. Selection of the Job

Selections of the jobs to be studied for methods improvement by the method study practitioner is a managerial responsibility and it (selection) may be based on economic technical or human consideration. Economic consideration justifies selection based on the economic worth (i.e. money saving potential) of the job. Technical consideration identifies jobs, which require studies to overcome manufacturing difficulties (excessive rejection, relaxation in prefixed performance standards, inability if the shops to stick to specified machining parameters such as speeds, feeds, depth of cut etc., inconsistent quality etc.) Human consideration in job selection is usually given weight-age while introducing method study practices for the first time.

2. Recording of Facts

Systematic recording is the most crucial step in method improvement. Since recording by long hand (or by descriptive method) has its limitations, it is not recommended for use in method study. Instead, five symbols and eight charting conventions are used to record facts relating to the job under study. Five typical symbols are O, ||, Ã , D and V and eight charting conventions concern composition of the chart, reject, rework, repletion, change of state, introducing of new material, combined events and numbering of events. The document on which details of the process are recorded by the above referred symbols and conventions is called chart. There are four basic types of chart: (i) operation process chart (ii) Flow process chart (iii) multiple activity charts and (iv) two handed process chart. Besides charts, two types of diagrams-flow diagram and string diagram are drawn when recording details of an existing layout. Travel chart is another typical chart, which is used to record frequency of movements (weight x distance) between work centers/departments. Repetitive short cycle operation that involves quick hand / feel motions (i.e. microscopic motions) may be studied with micro motion study. Glibreth, founder father of micro motion study, also developed photographic techniques called cyclograph and chronocylegraph to record path of the motions of the members of the body.

3. Critical Examination

Critical examination aims to analyze the facts critically and thereby give rise to alternatives, which form the basis of selection and development of easier, and effective methods. Critical examination is conducted through a systematic and methodical questioning process. Each activity recorded on the chart, whether it relates to processing or inspection, or material handling, or to any other aspect, is picked up one at a time and is examined minutely. The questioning process is considered under five major heads, namely the purpose, the place, the sequence, the person and the means. These five aspects in critical examination are referred to as five governing considerations.

4. Development and Selection

Development and selection stage concerns short listing of ideas generated at the critical examination stage, testing each short listed idea for its technical and economic feasibility, and making selection among the alternatives wherever choice exists. To develop ideas and to ascertain their technical and economical feasibility, the method study practitioner needs to solicit the cooperation of personnel from different departments of the company. Various techniques available for the development and selection purpose are: cost benefit analysis, break-even analysis, investment analysis and critical path analysis.

5. Installation

Installation (or implementation) of the proposed method involves preparation of project report on recommendations making oral presentation to the top management, securing approval of the decision maker, assisting line management during implementation, arranging training of workmen, and getting jobs (operations) re-time after implementation, arranging training of workmen, and getting jobs (operations) re-timed after implementation.

6. Maintenance

Maintenance phase is the follow up phase after implementation, which serves as a monitoring and control mechanism. It helps to ensure that the revised methods are set into concrete and workmen do not revert back to old methods. It also provides an opportunity to the practitioner to assess the effectiveness of the approach followed by him and makes changes in the methodology (if required).

The problem with expressing the procedure in such a simple manner is that undertaking a method study appears to be a simple, linear and mechanistic process. This description in six steps does however serve to show the underlying simplicity of the concept of method study. In practice, the method study procedure consists of a cyclical or iterative process in which each step may be revisited according to the findings of subsequent steps. For example, collecting data about a current situation often enables us to discover the reality behind our first perceptions and thus to refine our selection of what we are addressing. Similarly, when we start to examine data, we sometimes become aware that data are missing or incomplete and we need to go back and collect (record) additional data. This cyclic process often begins with a rough first pass, in which preliminary data are collected and examined, and progresses to a more detailed and thorough pass which results in the collection of more detailed and more complete data which is the subject of a more rigorous scrutiny. The method study procedure is thus a convenient representation of what may be a complex process.