A supply chain is a network of manufacturers, suppliers, distributors, transporters, storage facilities and retailers that perform functions like procurement and acquisition of material, processing and transformation of the material into intermediate and finished tangible goods, and finally, the physical distribution of the finished goods to intermediate or final customers.

Major Components of Supply Chain

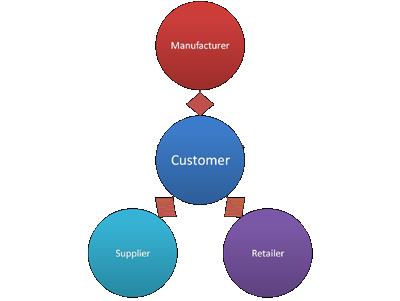

A supply chain may consist of variety of components depending on the business model selected by a firm. A typical supply chain consists of the following components:

- Customers: The customer forms the focus of any supply chain. A customer activates the processes in a supply chain by placing an order with the retailer. The customer order is filled by the retailer, either form the existing inventories, or by placing a fresh order with the wholesaler/manufacturer. In some cases a customer bypasses all these supply chain components by getting in touch with the manufacturers directly. For example in the case of an online purchase of a computer from Dell Computers, the customer places an order directly with the manufacturer.

- Retailers/Distributors: The retailer acts as a link between the customer and the distributor/manufacturer. He caters to the needs of the customer by making the products available at his store. As part of this process, the retailer places orders with the manufacturer to replenish the stocks. In a typical supply chain, purchase orders originate at the retailer’s end, but in some cases where there is arrangement to share, the POS information with manufacturers the manufacturer monitors the stock levels and replenishes it automatically, Wal-Mart has such an arrangement with P&G,

- Manufacturers: The manufacturer plays a key role in deciding the structure of supply chain. Depending on the market situation, the manufacturer either uses the pull or the push strategy to generate demand required for the movement of products in the supply chain. The manufacturer then plans for a production schedule depending on the resultant demand.

- Suppliers: Suppliers facilitate the manufacturers, production process by ensuring continuous supply of raw materials. Manufacturers place orders with suppliers on the basis of forecasted customer demand. Since it is very difficult to forecast demand accurately, manufacturers try to integrate their processes with those of the suppliers to be in a better position to respond to fluctuations in customer demands. Suppliers help manufacturers to decrease their inventory levels by arranging for Just-in-time supplies.

Supply chain management involves the use of a set of approaches to integrate efficiently the activities of suppliers, manufacturers, warehousing providers and retailers, so that goods are produced and distributed in right quantities, to the right locations, and at the right time, in order to minimize system-wide costs while meeting customer service expectations.