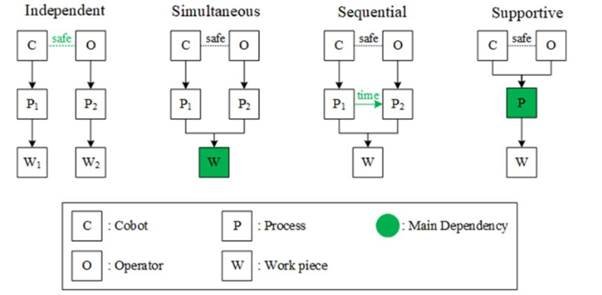

“Machines alone do not give us mass production. Mass production is achieved by machines and men.” – Henry Ford II ,1914 Above quote which said by Henry Ford, it doesn’t mean that human alone cannot achieve mass productions but with machines, mass productions can be easily achieved with the right machines. Computer-controlled, intelligent assist devices are a huge change in material handling technology today. The step changes in their ergonomics, productivity, quality and safety capabilies – especially when compared with tradition pneumatic tools which are considered old schooled in compared with cobots today. Cobots, or collaborative robots, are robots intended to interact with humans in a shared space or to work safely in close proximity. Cobots stand in contrast to traditional industrial robots which are designed to work autonomously with safety assured by isolation from human contact. Cobot safety may rely on lightweight construction materials, rounded edges, and limits on speed Continue reading

Operations Management

Failure Modes and Effect Analysis (FMEA) – Operation, Advantages, and Disadvantages

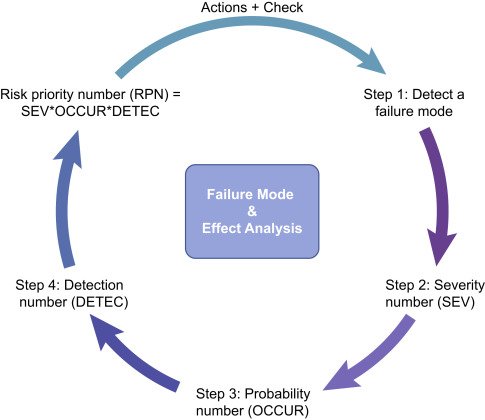

Risks are common occurrences that happen in the daily operations of an organization. They are uncertainties that occur as a result of certain activity and may result in loss of value or other immeasurable. Organizations must have risk control measures to ensure that risk identification, analysis, and mitigation are carried out effectively. Organizations spend a substantial amount of their budgets in developing risk management strategies. There are different tools that organizations employ in risks reduction practices. For instance, Failure Mode and Effect Analysis (FMEA) is a part of the quality assessment tool that allows a company to detect possible failures. The Failure Mode and Effect Analysis (FMEA) is one underlying concept of continuous quality improvement.FMEA is an analytic activity carried out on a product, service or process in order to know its strengths and weaknesses, deal with a potential problem before it occurs and ensure that it meets the set Continue reading

The Pareto Principle Explained (The 80/20 Rule)

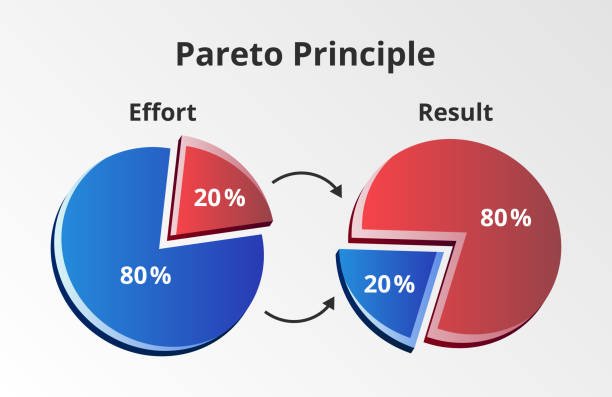

What is the Pareto Principle? Vilfredo Federico Damaso Pareto was an Italian economist, he discovered that in any situation twenty percent of the inputs/activities are responsible for eighty percent of the outputs/results. In 1906, he discovered that 80% of the land in Italy was owned by only 20% of the people. Later he recognized that same lop-sided relationship applied to other things as well. Pareto first discovered this law in his own garden. He noticed that twenty percent of his pea pods, created eighty percent of the peas, as an economist he then drew parallels to Italy’s economy, discovering that eighty percent of the land belonged to twenty percent of the population. Pareto’s Principle basically states that a small number of reasons are responsible for a large percentage of the effect; this ratio is usually 20% of the cause to 80% of the effect, or 20:80. However, this principle was Continue reading

The Baldrige Framework for Performance Excellence

In the business world, the realization of business excellence is pivotal towards fostering the success of an enterprise. In this respect, business organizations need to engage in actions that facilitate performance excellence. The areas of business operations that need a considerable extent of excellence include customer satisfaction, workforce fulfillment, operations efficiency, and business growth. The need for continuous improvement influences business managers to adopt the suitable performance excellence models. The Baldrige Excellence Framework is one of the most sought-after performance excellence models that drive the success of businesses in different sectors. The model mainly focuses on bolstering performance excellence by improving the business aspects of leadership, strategic planning, customer supervision, workforce administration, knowledge management, and operations focus. Business organizations need to focus on improving the performance of the mentioned aspects to realize significant excellence in their respective industries. Background In the mid-1980s, leaders in the United States saw the need Continue reading

Comparing Six Sigma and Total Quality Management (TQM)

Six Sigma Six Sigma is the management technique based on project development and improving critical services and products of a firm. Therefore, Six Sigma aims to reduce product defects, reduce maintenance costs, and increase production effectiveness and efficiency to achieve these improvements. The techniques also aim at improving the understanding and satisfaction of clients’ needs and corporate governance by enhancing the competitive advantage of firms. The mechanism improves productivity and a company’s financial performance by establishing measures of correcting an organization’s internal controls. The primary aim of the Six Sigma mechanism is to improve the firm’s process capabilities by using various statistical tools. It reduces waste and eliminates costs that do not add value to the firm’s performance. The main objective of this technique is to improve service delivery and enhance customer satisfaction after correcting the critical business process which would cause delays in their performance. When the importance of Continue reading

Concurrent Engineering Vs Traditional (Sequential) Engineering Methods

Traditionally, products were designed and manufactured following the sequential engineering methods, where people from different departments work one after the other on successive phases of development. This method of production is in a linear format. The different steps are done one after another, with all attention and resources focused on that one task. After it is completed it is left alone and everything is concentrated on the next task. The product is first completely defined by the engineering design department, and then the manufacturing department take over and define the manufacturing process, etc. This was a lengthy process, and often led to a lot of design changes as the prototype testing began, due to production problems, delays or design flaws. This is therefore a slow and costly approach, often leading to a low-quality and less competitive product. Concurrent Engineering, sometimes called Simultaneous Engineering or Integrated Product Development (IPD), can be Continue reading