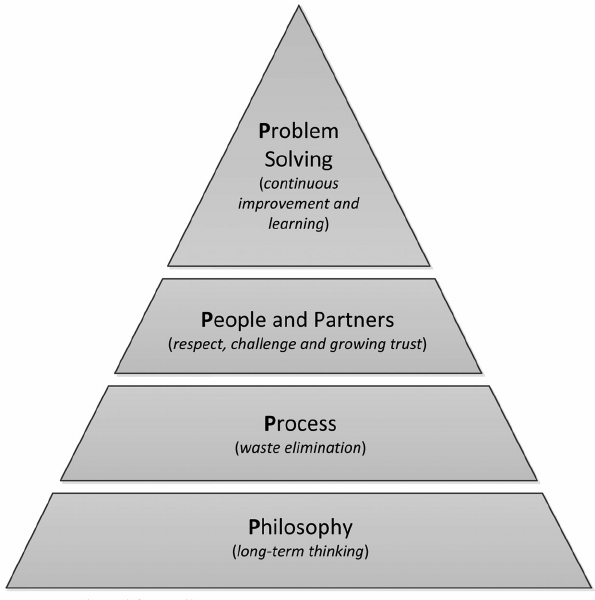

The fundamental reason for Toyota’s success in the global marketplace lies in the so called “Toyota way”. The Toyota Way is not only about technology and efficiency, it is about doing the right thing for the company, its employees, the customer and the society as a whole.

In other words, the incredible success of the Toyota way is a direct result of operational excellence. Toyota has turned operational excellence into a strategic weapon. This operational excellence is only in part based on tools and quality improvement methods made famous by Toyota in the manufacturing world, such as JIT, Kaizen, and one-piece-flow.… Read the rest