A venture isn’t fruitful in light of the fact that it has been finished on schedule and inside a spending plan. There is one other factor that is basic to progress: quality. Regardless of how rapidly and inexpensively a task is finished, partners won’t be upbeat if the nature of the item or administration doesn’t live up to their desires. Along these lines, one significant technique to follow and examine the nature of the task and ensure it meets the necessities of the clients is Quality affirmation. QA according to ISO 9000 is characterized as “a component of value the executives concentrated on giving certainty that quality prerequisites will be satisfied”.… Read the rest

Operations Management Concepts

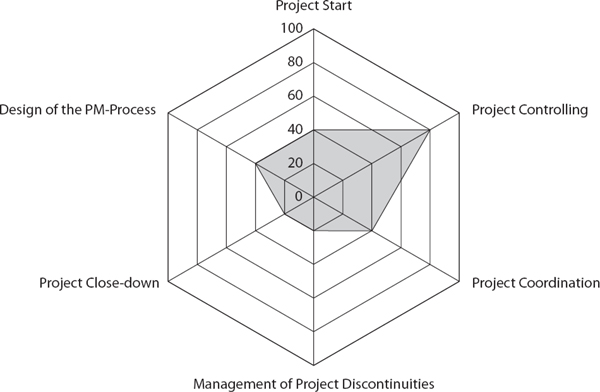

Roland Gareis Project Maturity Model

For managing the projects, project portfolios and programs, companies with project orientation have particular strategies, organizational structures, and certain cultures. The management of the programs and project provides competitive improvement for the social systems. Therefore, the organizations including nations, regions, industries are becoming more project oriented. There is an interrelationship between the outcomes of the project oriented systems in the project and their maturity state. These maturities of the project or an organization can be evaluated by different maturity models. In this article, the maturity model developed by the ROLAND GAREIS Project and Programme Management ® has been discussed.

Dr. Roland Gareis who is a university professor at the Vienna University of Economics and Business Administration, Austria. … Read the rest

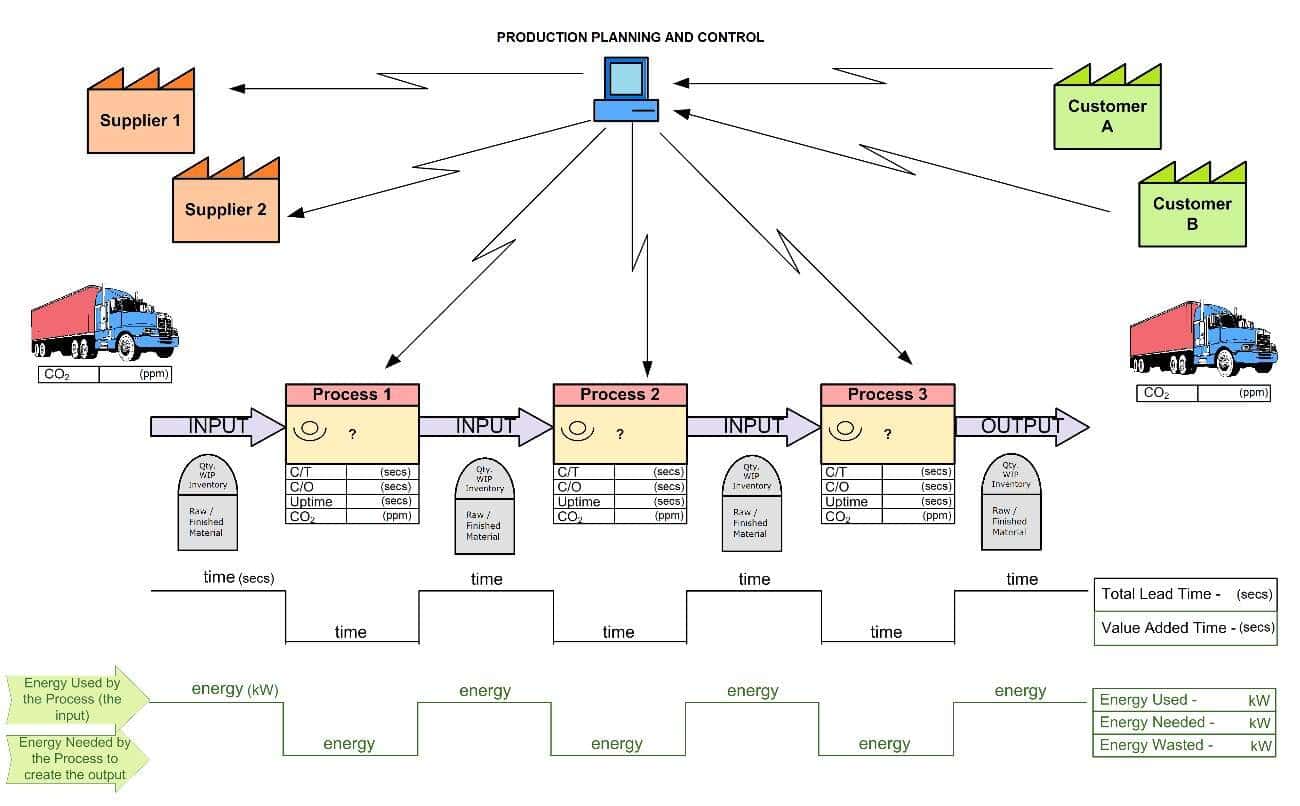

Energy Value-Stream Mapping (EVSM)

A typical Value Stream Mapping (VSM) tool classifies the various industrial processes into value adding and non-value adding with a goal to identify and eliminate the non-value added (waste) activities. Based on the concept of Value-Stream Methodology, Energy Value-Stream mapping (EVSM) is being developed where energy components along with cost are added to evaluate with respect to time.

Energy Value-Stream mapping (EVSM) identifies the level of energy utilization and wastage in each step and hence determines the opportunities for energy conservations. Implementing this tool by incorporating electrical energy and fuel consumption provides with an ability to view the impact that process improvements have on reducing energy consumption and vice versa.… Read the rest

Supplier Relationship Management (SRM) – Meaning and Importance

Supplier Relationship Management (SRM) is a concept in the Supply Chain Management, which considered in the aspect of establishing and sustaining the business relationship along the supply chain. Supplier Relationship Management (SRM) concerns the practical processes to integrate the communication and coordination between organizations and their suppliers.

Supplier chain relationship was considered to be one of the important factors in most business, since it can influence the potential of supply chain concept. Now, the modern business seems to be more complex with high competition. Due to the information has more valuable in the supply chain management, firms then need to re-design the ways of managing and sharing information among each others.… Read the rest

Cost Reduction – Meaning and Techniques

A cost reduction program is a type of method which is to improve profitability of the organization or by expected to get a good result that flow to the bottom line of the financial statement and exempted from any serious damage to the organization itself. As this program is much more about reducing cost or reducing expenses of the organization, so a good cost reduction program is all about how to control the damage of an organization. Furthermore, a cost reduction program is said to be improve the profitability of an organization because by reducing expenses, profits are increased without making others changes.… Read the rest

Kaizen Costing Method

Kaizen is a Japanese management concept launched by Masaaki Imai, which proved to be the key to Japanese competitive success. The significance of this concept is: KAI = Change and ZEN = for better, and the translation is “continuous improvement”, that means small improvements to the ongoing efforts. Unlike the Western conception, implying total change, at large intervals of time, using large amounts of resources and a high cost level, Kaizen Costing seeks daily, gradual, slow, but continuous improvements, which take place at minimal cost.

Kaizen strategy is that a single day should not pass without an improvement to intervene in the activity of each employee or each entity.… Read the rest