Definition of Production Control All organizations irrespective of size, use production control to some degree. In small organizations, the production control may be performed by one person; but in large complex industries the production control department is normally well-organised and highly specialized. Production control presupposes the existence of production plans, and it involves the use of various control techniques to ensure production performance as per plans. Co-ordinating men and materials and machines is the task of production control. Production control may be defined as “the process of planning production in advance of operations; establishing the exact route of each individual item, part of assembly; setting and finishing dates for each important item, assembly and the finished products, andContinue reading

Production Management

Production planning- Definition, Objectives and Levels

Production planning is concerned with deciding in advance what is to be produced, when to be produced, where to be produced and how to be produced. It involves foreseeing every step in the process of production so as to avoid all difficulties and inefficiency in the operation of the plant. Production planning has been defined as the technique of forecasting or picturing ahead every step in a long series of separate operations, each step to be taken in the right place, of the right degree, and at the right time, and each operation to be done at maximum efficiency. In other words, production planning involves looking ahead, anticipating bottlenecks and identifying the steps necessary to ensure smooth andContinue reading

Introduction to Production Management

Meaning Of Production Management A few definitions of production management are being reproduced here under to understand the meaning of the term clearly: “Production management is the process of effectively planning and regulating the operations of that part of an enterprise which is responsible for actual transformation of materials into finished products”. Elwood S. Buffa has defined the term in a broader sense as: “Production management deals with decision making related to production process so that the resulting goods or services are produced according to specifications, in amounts and by the schedules demanded and at a minimum cost”. Production management, thus, is assigned with the following tasks. Specifying and accumulating the input resources, i.e., management, men, information, materials, machine andContinue reading

Factors Influencing Plant Layouts

The basic objective of any plant layout is to ensure a smooth flow of work, material, and information through a system. The basic meaning of plant is the space in which a business’s activities take place. The layout and design of that space impact greatly how the work is done-the flow of work, materials, and information through the system. The key to good plant layout and design is the integration of the needs of people (personnel and customers), materials (raw, finishes, and in process), and machinery in such a way that they create a single, well-functioning system. Recommended reading: Plant layouts – Definition and Objectives The following are some important factors, which influence the planning of effective layout to aContinue reading

Techniques or Tools Used for the Design of Good Plant Layouts

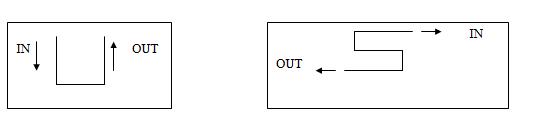

An ideal plant layout should provide the optimum relationship among output, floor area and manufacturing process. It facilitates the production process, minimizes material handling, time and cost, and allows flexibility of operations, easy production flow, makes economic use of the building, promotes effective utilization of manpower, and provides for employee’s convenience, safety, comfort at work, maximum exposure to natural light and ventilation. It is also important because it affects the flow of material and processes, labor efficiency, supervision and control, use of space and expansion possibilities etc. Recommended Reading: Plant layouts – Definition and Objectives In designing or improving the plan of plant layout, certain techniques or tools are developed and are in common use today. The techniques or toolsContinue reading

Plant Layouts – Definition and Objectives

Plant layout means the disposition of the various facilities (equipment’s, material, manpower etc.) within the areas of the site selected. Plant layout begins with the design of the factory building and goes up to the location and movement of work. All the facilities like equipment, raw material, machinery, tools, fixtures, workers etc. are given a proper place. Some definitions of Plant Layout are; In the words of James Lundy, “It identically involves the allocation of space and the arrangement of equipment in such a manner that overall cost are minimized”. According to MoNaughton Waynel, “A good layout results in comforts, convenience, appearance, safety and profit. A poor layout results in congestion, waste, frustration and inefficiency”. According to Andrew GreaslyContinue reading