The creation of Six Sigma Methodology is understood to be traced back to Carl Friedrich Gauss and introduced as a measurement in variation in organizations. Six Sigma name comes from the Greek alphabet “Sigma” which mathematician or statisticians uses in statistics to find a standard deviation. Motorola was the first company to use Six Sigma, to measure the quality of products and services from within. In the process of Motorola using Six Sigma, it helped them to pinpoint mistakes such as finances and operations. Six Sigma’s core philosophy was based on business process and customer requirements, extensive training to employees, focus on the organization, and creating an improved system.… Read the rest

Quality Management

Improvements In Productive Flow And Product Quality

The main objective of any business is profit making which it derives by making its products and services available to people. The business models therefore, can be described as value propositions for various stakeholders for which the management evolves strategies and methodologies to create goods and services in some particular arena and delivers the same to the desired target group or customers. It explains how the business would function, identify the goods and services that would be produced for identified customers, ensure the viability of the objectives and goals of the business to deliver values based services. In the contemporary environment of highly competitive business, innovative managerial practices become critical for increasing profitability without major capital investment.… Read the rest

Cost Reduction – Meaning and Techniques

A cost reduction program is a type of method which is to improve profitability of the organization or by expected to get a good result that flow to the bottom line of the financial statement and exempted from any serious damage to the organization itself. As this program is much more about reducing cost or reducing expenses of the organization, so a good cost reduction program is all about how to control the damage of an organization. Furthermore, a cost reduction program is said to be improve the profitability of an organization because by reducing expenses, profits are increased without making others changes.… Read the rest

Seven Management and Planning Tools

Competition level within every industry is constantly growing and businesses try to find any possible ways to improve quality of products and services. However, quality is quite a complex concept that can be viewed as a measure of perfection. Quality improvement leads to a perfect product that is meant to satisfy the customer. In the early 1980s, the seven management and planning tools were designed as major tools for effective planning and management of processes, which are above the quality operation.

They are as follows:

1. Affinity DiagramsThe first of the tools in the list is Affinity diagrams. The affinity diagram is a visual brainstorming instrument that can be used to categorize various facts and data, ideas and opinions by a proximity factor.… Read the rest

Important Aspects of Total Quality Management (TQM)

Total Quality Management (TQM) is a management philosophy that supports the process of continuous improvement within an organization and where total emphasis is placed on the customer. In the socioeconomic viewpoint, TQM defines the customer as all members of society and facets of environment that interact with the activities of the company. TQM is also defined as a set of management practices throughout the organization, geared to ensure the organization consistently meets or exceeds customer requirements. The goal of TQM philosophy is – “Do the right things right the first time, every time.” One of the principal aims of TQM is to limit errors to 1 per 1 million units produced.… Read the rest

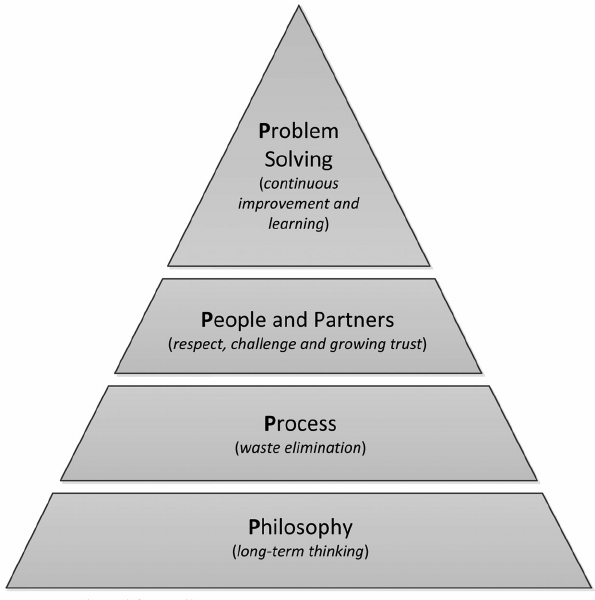

Analyzing Toyota’s Recipe for Success – The Toyota Way

The fundamental reason for Toyota’s success in the global marketplace lies in the so called “Toyota way”. The Toyota Way is not only about technology and efficiency, it is about doing the right thing for the company, its employees, the customer and the society as a whole.

In other words, the incredible success of the Toyota way is a direct result of operational excellence. Toyota has turned operational excellence into a strategic weapon. This operational excellence is only in part based on tools and quality improvement methods made famous by Toyota in the manufacturing world, such as JIT, Kaizen, and one-piece-flow.… Read the rest