“Machines alone do not give us mass production. Mass production is achieved by machines and men.” – Henry Ford II ,1914

Above quote which said by Henry Ford, it doesn’t mean that human alone cannot achieve mass productions but with machines, mass productions can be easily achieved with the right machines. Computer-controlled, intelligent assist devices are a huge change in material handling technology today. The step changes in their ergonomics, productivity, quality and safety capabilies – especially when compared with tradition pneumatic tools which are considered old schooled in compared with cobots today.

Cobots, or collaborative robots, are robots intended to interact with humans in a shared space or to work safely in close proximity. Cobots stand in contrast to traditional industrial robots which are designed to work autonomously with safety assured by isolation from human contact. Cobot safety may rely on lightweight construction materials, rounded edges, and limits on speed or force. Safety may also require sensors and software to assure good collaborative behaviour. The International Federation of Robotics (IFR), a global industry association of robot manufacturers and national robot associations, collects statistics on two types of robots –

- Industrial robots used in manufacturing, and

- Service robots for domestic and professional use.

Service robots can be considered to be cobots as they are intended to work alongside humans. Industrial robots have traditionally worked separately from humans, behind fences, but this is changing with the emergence of industrial cobots.

Cobots can have many roles. Collaborative service robots can perform a variety of functions, from information robots in public spaces; logistics robots that transport materials within a building, to inspection robots equipped with cameras and visual processing technologies that can serve in a variety of applications such as patrolling perimeters of secure facilities. Collaborative industrial robots can be used to automate repetitive, unergonomic tasks – such as fetching and carrying heavy parts, machine feeding and final assembly. Industrial robots have traditionally been used in industrial sectors for pre-assembly tasks such as cutting, welding, basic assembly of car bodies and painting. Collaborative industrial robots enable automotive and electronics manufacturers to extend automation to final product assembly, finishing tasks (for example polishing and applying coatings), and quality inspection.

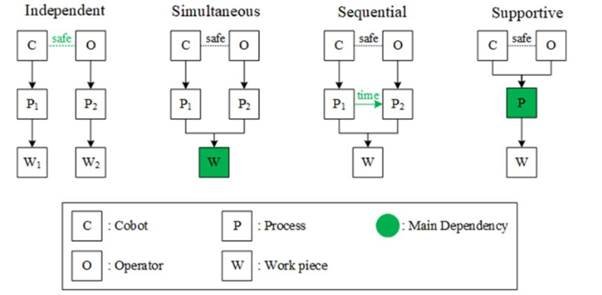

Cobot can also be categorised into as following:

- Independent – An operator and a cobot operate on separate workpieces (W1 and W2 illustrated in Figure) independently for their individual manufacturing processes (P1 for W1 and P2 for W2). The collaborative element is due to the co-presence of the operator and cobot in the same workspace without a fence or guard. That is safety is achieved through the cobot’s intrinsic safety and/or added hardware/software safety elements. Therefore, the cobot is aware of the opera-tor’s presence and acts safely.

- Simultaneous – An operator and a cobot operate on separate processes (P1 and P2 respectively) on the same work piece (W) at the same time. There is no time or task dependency between them. However, the cobot needs to be spatially aware of the operator and his/her task requirements in order to respect the operator’s space. Being able to concurrently operate on the work piece will minimise the transmit time of the work piece between the cobot and human, thereby improving productivity and space utilisation.

- Sequential – An operator and a cobot perform sequential manufacturing processes (P1 and P2) on the same workpiece. There are time dependencies between the cobot and operator for their processes. For instance, the cobot works on P1 for the work piece as an input to support the operator to carry on P2 for the work piece. In most cases, the cobot is arranged to handle tedious processes to improve the operator’s working conditions

- Supportive – An operator and a cobot work towards the same process (P) on the same work piece (W) interactively. There is dependency between the actions of the cobot and the operator. That is, without one, another cannot perform the task. The cobot needs to understand the operator’s intent and the task requirements in order to provide appropriate assistance. For instance, the operator fastens screws on a toolbox while the cobot holds it in place. The role of the cobot is to physically assist the operator with work pieces which improves ergonomics.

The Roles that Cobots Play

The typical workshop has been transformed by the advent of robots. From an unsafe, harsh conditions have been mitigated while simultaneously freeing up workers for tasks that are more enjoyable and less stressful.

The ergonomics and productivity consequences brought by manufacturing across all industries are documented as follows:

- 43% of worker sustained injuries and illnesses were due to bodily reaction and exertion;

- 62% of all illness cases were due to repeated trauma disorders;

- > 32% of cases involving days away from work resulted from overexertion or repetitive motion.

The total cost of this consequences to the US industries are enormous and it happens every year. The impact of this problem is so big such that shouldn’t be ignored.

Cobots are created to address some of the above problems. And it not only just for the whales in industries, and also for small and medium businesses. (SMBs) Cobots help meet the short-run production challenge faced by many SMBs, bridging the gap between fully manual assembly and fully automated manufacturing lines. This is helping small business owners address overseas competition with affordable automation solutions that can be deployed in a wide range of applications. As these small businesses compete more effectively, their growth can drive the use of additional automation solutions, including multiple cobots—or another form of collaboration, between cobots and traditional industrial robots for high-speed, repeatable applications.

Another good thing about cobot is that it can be highly cost-effective as it can be programmed to operate 24/7 in lights out situations for continuous production.

The Relevance of Cobots in Manufacturing

Manufacturing companies are eager to deploy cobots due to their affordability, builtin safety and intuitive User Interfaces (UIs). That is especially true for SMEs that have difficulties automating their manufacturing using traditional robots. Mass production companies, particularly the automotive manufacturers, are equally eager to implement HRC to boost their competitiveness and take their factories to the next level of automation and manufacturing advancement, i.e. Industry 4.0. For instance, the BMW Group’s Spartanburg site introduced cobots to improve ergonomics by taking over the repetitive and precise task of equipping the inside of car doors with sound and moisture insulation. Audi introduced a UR3 cobot to apply an adhesive on a car roof, which saves factory floor space since the cobot does not have to be separated from the human by a fence. The Volkswagen plant in locations that are inconvenient to reach by a human operator. The cobot works alongside the human who is screwing at other easily accessible locations. Nissan’s large-scale Yokohama plant deployed UR10 cobots to loosen bolts and carry heavy components to relieve the workforce of these arduous tasks and speed up the manufacturing process. Skoda also introduced a KUKA cobot to work alongside humans in the production of direct-shift-gearboxes. In all the aforementioned tasks, cobots are required to operate safely alongside humans, which is a built-in feature in cobots. However, they do not strictly require advanced perception, human awareness or decision-making capabilities since the parts handled are kept in pre-determined positions, the tasks of the human and the cobot are relatively independent, and the cobot adheres to a relatively fixed action/motion plan. Therefore, it is noticeable that industrial implementation of HRC scenarios fall under the category ”Independent” or ”Simultaneous”. However, by enforcing additional constraints upon the cobots’ environment (in terms of fixed parts or equipment positions), most of such implementations fail to showcase the utility and versatility of cobots in a partially unstructured work environment.

However, human rely a lot on communication to work in teams and to complete tasks fluently and effectively. Communication can be made to issue orders, convey intention and ask/answer questions. Researchers have been working on enabling communication between humans and cobots such that the human is able to command the cobot through different communication modes.

First and foremost, body language and speech. Body language as a means of commanding cobot includes using gestures, pointing, head pose, etc. Speech refers to uttering commands verbally. But, at the end of the day, cobots aren’t human, they need to be trained in order to be able work alongside with human. They learn while they work through machine learning. Communications can be complex as for example, different gestures/commands can mean differently in different situation. This is can avoided by such and such command to be predefined strictly in a fixed set.

Generating a natural language system is challenging since the language use differs drastically as the operator progresses with work. In a collaborative task where only verbal communication is allowed, the frequency of morphemes (i.e. words belonging to these certain types: object, modifier, robot action, user action) decreases as the number of task trials increase. That is because humans naturally start emitting words as they become accustomed to the task. They naturally start considering and accommodating their team-mates’ needs without those needs being explicitly expressed. The use of descriptive words decreases as the number of task trials increase. Therefore, any language model between a human and a cobot should account for the change in human language as the human becomes more accustomed to the task.

Cobots in Eliminating Manufacturing Jobs

Cobots not only doesn’t eliminate manufacturing jobs, it also provides more job opportunities, make manufacturers even more globally competitive. This is because cobots are available for everyone not only for the big companies. In manufacturing work, a lot of manpower are needed previously. Now, cobots free up a lot of manpower to let companies maximizes worker’s skills in other areas of business. It also creates a safer, more desirable working environment for workers as the job that cobots do are usually boring and repetitive, dangerous.

Not only that, some countries which lack of manpower in mass production line are already fixed with cobots available. Today’s labour market includes fewer skilled manufacturing workers due to decades of offshoring, and cobots come in handy to eliminate the shortfall.

Talk about globally competitive, automation in manufacturing allows domestic companies to be price-competitive with offshore companies because of mass production in a shorter time span. As cobots are available 24/7 of the time, it increases the production rate of the product to meet the demand rate with the minimal costs. As cobots are able to do work precisely and quickly, it is always able to achieve customer’s desire in which easily offsetting their upfront costs as well. Cobots are good in helping manufacturers breaking the ceiling of output capacity as well. Last but not least, cobots are economically friendly as well. It not only doesn’t emit green houses, it also helps is reducing the energy consumption of factory as well, cobots doesn’t need lighting to function 24/7 so it is able to create cleaner spaces also.