Cause and Effect diagram are a graphical method for finding the most likely causes for an undesired effect. The Cause and Effect diagram also known as the fishbone diagram or Ishikawa diagram after its creator Kaoru Ishikawa is used to systematically list all the different causes that can be attributed to a specific problem (or effect). A cause and effect diagram can help identify the reasons why a process goes out of control.

The Ishikawa diagram is one of the seven basic tools of quality control, which include the histogram, Pareto chart, check sheet, control chart, cause-and-effect diagram, flowchart, and scatter diagram.

The purpose of this diagram is to arrive at a few key sources that contribute most significantly to the problem being examined. These sources are then targeted for improvement. The diagram also illustrates the relationships among the wide variety of possible contributors to the effect.

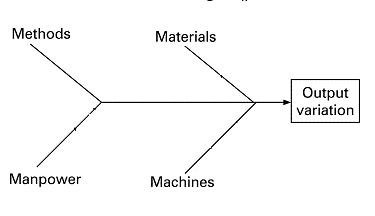

The basic concept in the Cause-and-Effect diagram is that the name of a basic problem of interest is entered at the right of the diagram at the end of the main “bone”. The main possible causes of the problem (the effect) are drawn as bones off of the main backbone. The “Four-M” categories are typically used as a starting point: “Materials”, “Machines”, “Manpower”, and “Methods”. Different names can be chosen to suit the problem at hand, or these general categories can be revised. The key is to have three to six main categories that encompass all possible influences. Brainstorming is typically done to add possible causes to the main “bones” and more specific causes to the “bones” on the main “bones”. This subdivision into ever increasing specificity continues as long as the problem areas can be further subdivided. The practical maximum depth of this tree is usually about four or five levels. When the fishbone is complete, one has a rather complete picture of all the possibilities about what could be the root cause for the designated problem.

The Cause and Effect diagram can be used by individuals or teams; probably most effectively by a group. A typical utilization is the drawing of a diagram on a blackboard by a team leader who first presents the main problem and asks for assistance from the group to determine the main causes which are subsequently drawn on the board as the main bones of the diagram. The team assists by making suggestions and, eventually, the entire cause and effect diagram is filled out. Once the entire fishbone is complete, team discussion takes place to decide on the most likely root causes of the problem. These causes are circled to indicate items that should be acted upon, and the use of the tool is complete.

How to Construct an Ishikawa Diagrams or Fishbone Diagrams

- Place the main problem under investigation in a box on the right.

- Generate and clarify all the potential sources of variation.

- Use an affinity diagram to sort the process variables into naturally related groups. The labels of these groups are the names for the major bones on the Ishikawa diagram.

- The process variables are then placed on the appropriate bones of the Ishikawa diagram.

- Combine each bone in turn, insuring that the process variables are specific, measurable, and controllable. If they are not, branch or “explode” the process variables until the ends of the branches are specific, measurable, and controllable.

The Ishikawa diagram, like most quality tools, is a visualization and knowledge organization tool. Simply collecting the ideas of a group in a systematic way facilitates the understanding and ultimate diagnosis of the problem. Several computer tools have been created for assisting in creating Ishikawa diagrams.