The concept of Value Chain was propagated by Michael Porter in the 1980s in his book “Competitive Advantage: Creating and Sustaining Superior Performance” (Porter, 1985), as a tool of analyzing the firm’s internal environment and resource base. Value Chain Analysis is an analytical tool that describes all activities that make up the economic performance and capabilities of the firm, used to analyze and examine activities that create value for a given firm. A firm can be conceived of an aggregation of discrete activities and the competitive edge arises based on how a firm performs these activities better than its competitors. The cluster of these activities is called the value chain.

According to Porter: “Competitive advantage cannot be understood by looking at a firm as a whole. It stems from the many discrete activities a firm performs in designing, producing, marketing, delivering and supporting its product. Each of these activities can contribute to a firm’s relative cost position and create a basis for differentiation” (Porter, 1985:33)

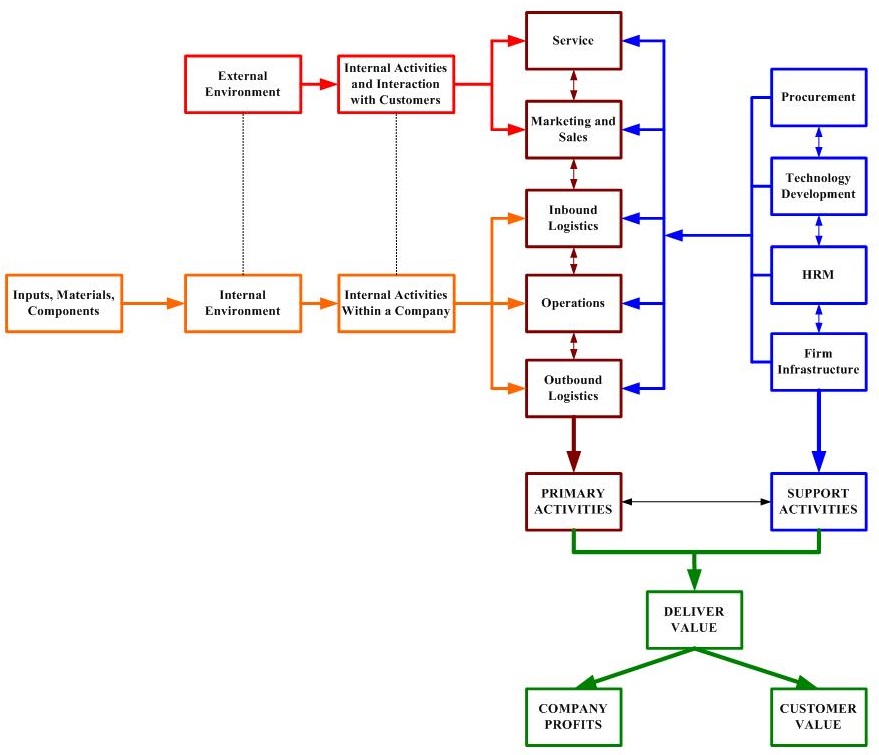

The value chain classifies each firm’s activities into two broad categories: Primary activities and Secondary activities or support activities. The following figure represents the value chain of a firm:

Primary Activities:

The sequence of activities through which raw materials are transformed into benefits enjoyed by the customer is called primary activities.These activities relate directly to the actual creation, development, manufacture, distribution, sales and servicing of the product or the service to a customer. Five major activities are involved in this sequence: inbound logistics, operations, outbound logistics, marketing and sales and service. Working together, these activities determine the key operational tasks surrounding the product or services.

- Inbound Logistics: As the word implies, inbound logistics deal with the handling of raw materials and inventory received from the firm’s suppliers. Detail activities include Receiving, storing, materials handling, warehousing, inventory control, vehicles scheduling and returns to suppliers.

- Operations: Operations are the activities and procedures that transform raw materials, components and other inputs into finished end products. Detail activities include machining, packaging, assembly, equipment maintenance, testing, printing, facility operations.

- Outbound Logistics: Outbound logistics refers to the transfer of finished product to the distribution channel members. The focus of outbound logistics is on managing the flow and distribution of products to the firm’s immediate customers such as wholesalers and retailers. Activities and procedures associated with outbound logistics include inventory control, warehousing, order processing, delivery schedule maintenance etc.

- Marketing and Sales: Marketing and sales include advertising, promotion, product mix pricing, specifying distribution channel members, maintaining channel relations etc in order to induce and facilitate buyers to purchase the product.

- Service: Customer service is a central value adding activity that a firm can seek to improve over time. It includes installation, repair, training, parts supply and product adjustment in order to maintain or enhance the value of the product after sales.

Porter’s Value Chain – Primary Activities: A Summary

|

Primary Activities

|

Inbound Logistics

|

– Receipt of inputs (materials)

– Storage – Stock Control – Internal Distribution of Inputs |

|

Operations

|

– Transformation of inputs into final product

– Use of Labor – Manufacturing Technologies |

|

|

Outbound Logistics

|

– Distribution of finished goods

– Stock Control & Inventory – Distribution of final product to buyers |

|

|

Marketing & Sales

|

– Advertising

– Promotional Activity – Persuading People to buy |

|

|

Service

|

– After sales support

|

Secondary or Support Activities:

The remaining activities of the value chain are undertaken to support primary activities. They are therefore referred to as the secondary or support activities. Support activities help the firm improve co-ordinations across and achieve efficiency within the firm’s primary value adding activities. Support activities are located across the first four rows of the diagram. This includes, procurement, technology development, human resource management and firm level infrastructure.

- Procurement: Securing inputs (such as raw materials, supplies, and other consumable items and assets) for primary activities.

- Technology Development: Methods of performing primary activities are improved (Such as know-how, procedures, technological inputs needed)

- Human Resource Management: Employees who will carry out the primary activities are recruited, trained, motivated and supervised.

- Firm Infrastructure: Activities such as accounting, finance, legal affairs, and regulatory compliance are carried out to provide ancillary support for primary activities.

Porter’s Value Chain – Secondary Activities: A Summary

|

Secondary Activities

|

Procurement

|

– Purchasing of Resources

– Purchasing of inputs |

|

Technology Development

|

– Technology to support primary activities &

operations

|

|

|

Infrastructure

|

– Leadership Structure/Management

– Planning/processes – Finance – Information Systems |

|

|

Human Resource Management

|

– Recruitment

– Selection – Training – Reward & Motivation

|

Porter also derives the concept of “margin” which is the difference between total value and the collective cost of performing the value activities.

Linkage Between Primary and Secondary Activities

Porter (1985) notes that value analysis cannot be sufficient to guide strategic decision making; the linkages between the different activities are also essential.

According to Porter : “Value activities are related by linkages within the value chain. Linkages are relationships between the way one value activity is performed and the cost or performance of another.” (Porter, 1985: 48)

The following figure explains the relationships between primary and secondary activities and separates the primary activities into internal and external environment. The starting point is the purchase of inputs, raw materials and components. Those are delivered into a company’s internal environment. Activities such as inbound logistics facilitate the processes where all the inputs are stored and distributed internally. Operations in turn are responsible to develop an output where it will be delivered to the customer by various activities carried out by the outbound logistics. The remaining primary activities, Sales, Marketing, and Service consist of numerous activities that facilitate interaction with the external environment which is the customers (on the hand to convince them to purchase the product and on the other hand, to support them in using it). Support Activities interact with the primary ones with purpose to deliver value for the organisation but as well as for the end user.

Value Chain Analysis and Strategic Planning

As already stated, the competitive edge arises based on how better the firm performs the activities involved in the value chain compared to its competitor. For this purpose, each activity is broken up in sun activities for comparison with the competitors, and three basic questions are tried to be answered?

- How can the firm keep the benefits provided to the customers intact keeping the cost constant?

- How can the firm increase the benefits provided to the customers keeping the cost constant?

- How can the firm increase the benefits provided to the customer while lowering the cost?

For creating competitive advantage through the value chain analysis while answering these questions, Porter has suggested the following measures;

- Reconfigure the value chain differently from those of the competitors.

- Perform the activities more efficiently than the competitors.

- Outsource the non-core activities:

While outsourcing the following points are needed to be judged judiciously;

- There might be a risk of non-performance by the supplier, To avoid this, ways of keeping alternative suppliers, tapered integration and part outsourcing can be adopted.

- There might be a risk of disproportionate value appropriation

- There can be a high risk of elimination by suppliers.

Internal integration of value chain activity gives the following benefits;

- Improvement of quality

- Shorten new product development cycle.

- By integrating the firm with its external suppliers and buyers it can reduce inventory holding costs, enhance the ability to customize the product and become more responsive to customers demand.

The point to be noted that throughout the whole analysis every measures are to be taken on the basis of comparison with suppliers.

External Links:

- Porter’s Value Chain (Mind Tools)